Allyl Diglycol Carbonate (ADC)

Properties

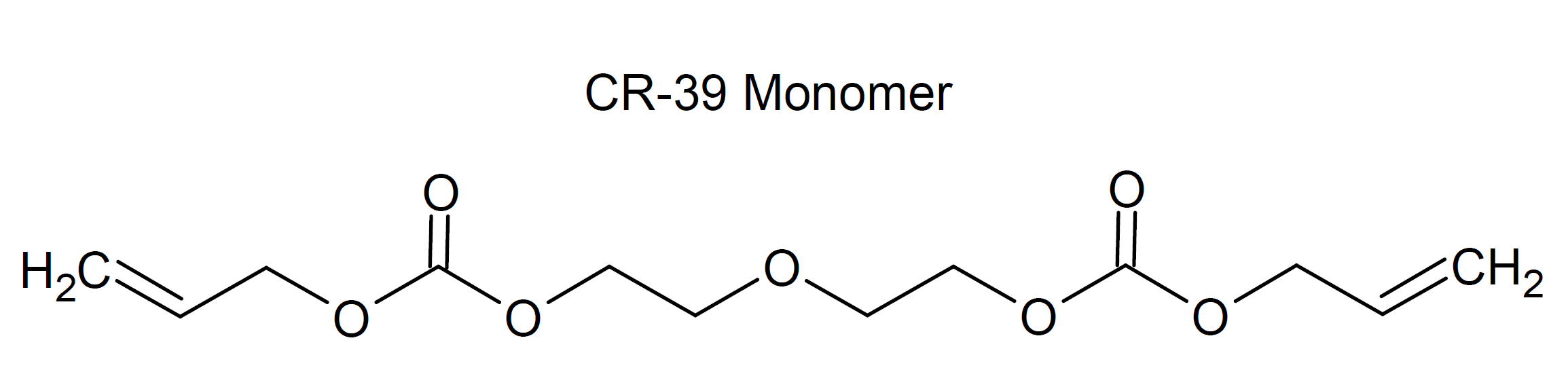

Allyl diglycol carbonate (ADC), also known as diethlyene glycol bis allyl carbonate, is a transparent and optical clear and very durable engineering thermoset resin that is essentially transparent to visible light. ADC was developed by the chemists at PPG who patented allyl diglycol carbonate in 1940. However, due to the war, the patent was not issued until 1945.1 The monomer is sold under the trade-marked name CR-39. This abbreviation stands for "Columbia Resin #39", which was the 39th version of this thermosetting resin developed by the Columbia Resins project in 1940.2

ADC can be polymerized to a hard polymer with no gas evolution, using a peroxide initiator such as diisopropyl peroxydicarbonate (IPP).3 The resulting resin can be cast into optical clear products. It can also be copolymerized with other unsaturated monomers such as vinyl acetate, methyl methacrylate, allyl methacrylate, styrene and maleic anhydride to improve certain properties such as heat distortion temperature and impact resistance, or to modify its spectral transmission characteristics.4,5

Compared to most other optical clear plastics, ADC (co)polymers

offer better resistance to abrasion

(scratching), heat, radiation, and most household chemicals.5 For this reason and

because of its light weight, ADC and its copolymers are often the

preferred materials for eyewear lenses, which is the main

application of this plastic. Other noteworthy optical uses include

protective covers for welding lenses, safety shields, lenses for

optical instruments, reflectors, and photographic filters.

The (recycled)

resin finds uses as a (less aggressive) blast media and as a friction modifier in coatings.

Manufacturers

|

Brand Names |